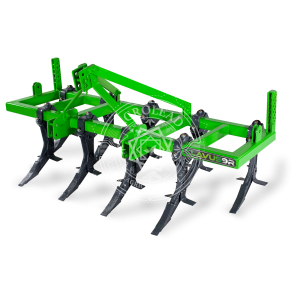

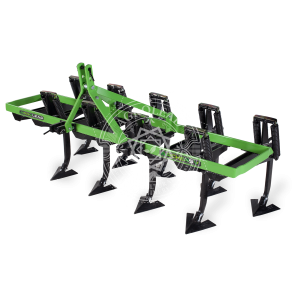

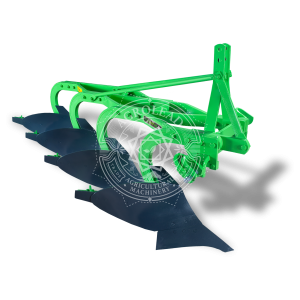

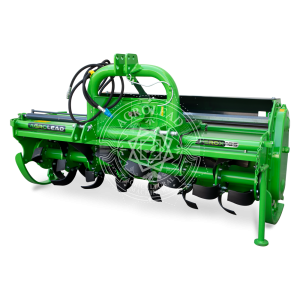

Compactor Heavy-Duty Cultivator

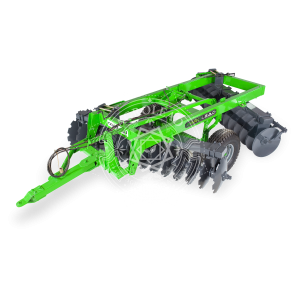

The Compactor Heavy-Duty Cultivator is designed for effective post-harvest stubble ploughing and secondary soil tillage. It mixes plant roots into the soil efficiently without overturning, which helps prevent soil erosion and conserves soil moisture. Equipped with pressure springs, it ensures stable ploughing even in heavy soil conditions. The combination of grading discs and rollers allows for quick and practical seedbed preparation.

The cultivator’s body is crafted from specially alloyed, heat-treated materials, enhancing both flexibility and durability. It offers adjustable ploughing depths and blade options to accommodate various working conditions. The versatile Compactor Heavy-Duty Cultivator is ideal for multiple soil processing tasks, including effective stubble processing after harvest. By cutting stubble from the root level and blending it into the soil, it promotes organic fertilization for the next crop cycle. Compactor is produced as mounted and trailed types in our production line.

Optimal Efficiency, Minimal Time Achieve maximum efficiency with operating speeds between 8-12 km/h, allowing you to complete tasks in the least amount of time possible.

Fuel-Efficient, Cost-Effective The compact design minimizes tractor power needs, and the ideal blade cutting angles lead to fuel savings and reduced operational costs.

Damage-Free Operation Each tine is equipped with strong springs that ensure continuous operation at the set working depth, offering 30 cm of flexing capacity to deliver a smooth ride and prevent tine damage.

Durable Tine Structure Apollo’s tines feature a robust spring safety mechanism, built to withstand harsh conditions and impacts. The safety spring opens under a ground resistance of 800 kg, ensuring durability.

Long-Lasting Bearing Housing The roller bearings are maintenance-free, lubrication-free, and designed for extended use, offering robustness and reliability.

Simple Depth Adjustment Adjust the working depth with ease using 5 mm, 10 mm, or 20 mm aluminum spacers. The roller height can be modified manually or hydraulically for optimal operation.

Safe and Secure Transport For machines with a working width of 4 meters or more, the hydraulic folding system reduces the transport width to 3 meters. Special safety locks and mechanical locking of hydraulic cylinders ensure a secure and safe road position.

| TECHNICAL FEATURES | UNIT | MODEL | ||||||

| COMPACTOR 3000 | COMPACTOR 3500 | COMPACTOR 4000F | COMPACTOR 4500F | COMPACTOR 5000F | COMPACTOR 5000T | COMPACTOR 6000T | ||

| Number of Tine | pcs | 10 | 12 | 13 | 15 | 17 | 17 | 19 |

| Number of Levelling Disc | pcs | 8 | 8 | 10 | 10 | 12 | 12 | 14 |

| Underbeam Clearance | cm | 78 | 78 | 78 | 78 | 78 | 78 | 78 |

| Working Width | mt | 3 | 3,5 | 4 | 4,5 | 5 | 5 | 6 |

| Transport Width | mt | 3 | 3,5 | 2,7 | 2,7 | 2,7 | 2,7 | 2,7 |

| Working Depth | cm | 8*25 | 8*25 | 8*25 | 8*25 | 8*25 | 8*25 | 8*25 |

| Required Power | hp | 100-160 | 120-190 | 160-210 | 180-240 | 200-260 | 240-360 | 240-360 |

| Weight With Q500 Tube Roller | kg | 1650 | 1920 | 2840 | - | - | - | - |

| Weight With Q500 Tube Double Roller | kg | - | - | - | 3100 | 3300 | 5400 | 5800 |

| Linkage | type | Std Hitch Pin Cat 3 / Cat 3N | Std Hitch Pin Cat 3 / Cat 4N | Std Cross Shaft Cat 3 / Cat 4N | ||||

| Transport Tyres | inch | 400/60-15,5 (ops 500/50-17) | ||||||